Web Menu

Product Search

Exit Menu

What are the environmental considerations when using a Transparent Dome PET Plastic Packaging Box?

Material Source and Production Impact

Transparent dome PET plastic packaging boxes are primarily made from polyethylene terephthalate (PET), which is a petroleum-based thermoplastic derived from non-renewable fossil fuels. The production of PET involves chemical synthesis and polymerization processes that consume significant amounts of energy and release greenhouse gases into the atmosphere. While PET is lighter than alternatives like glass, which can reduce transportation-related emissions, the initial environmental cost of extracting petroleum and manufacturing the resin is considerable. In addition, the production process can generate industrial by-products and waste that must be properly managed to prevent environmental contamination. Companies considering PET packaging need to evaluate this upstream environmental footprint and weigh it against the benefits of durability, transparency, and product protection.

Recyclability

One of the key advantages of PET as a packaging material is its high recyclability. PET containers, including dome-shaped boxes, can be collected through municipal curbside recycling programs or industrial recycling systems. Once collected, PET can be reprocessed into new packaging materials, fibers for textiles, or other plastic products. However, the efficiency of recycling depends heavily on proper waste management practices. Labels, adhesives, or residual product contamination can hinder the recycling process, lowering the quality of recycled PET (rPET) and potentially causing material to be diverted to landfills. Therefore, proper consumer education, clean disposal, and separation practices are critical to ensuring PET packaging enters the recycling stream successfully. Utilizing recycled PET in production can also reduce energy consumption and greenhouse gas emissions compared to virgin PET.

Energy Use and Carbon Footprint

The production and processing of PET involve considerable energy consumption, contributing to its overall carbon footprint. Despite being lightweight—which reduces emissions associated with shipping—PET still requires energy-intensive chemical processing. The use of recycled PET (rPET) can significantly reduce this environmental burden, as the recycling process consumes less energy than producing virgin PET resin. Using thinner walls or optimized designs for dome packaging can reduce material use while maintaining structural integrity, further reducing the carbon footprint. Evaluating energy use across the entire lifecycle—from raw material extraction to manufacturing, transportation, and disposal—is essential to understanding the full environmental impact of PET packaging.

Waste Management Challenges

Although PET is durable and protects products effectively, it is non-biodegradable and can persist in landfills or natural environments for hundreds of years if improperly disposed of. PET waste that enters waterways can break down into microplastics, which have been shown to negatively impact aquatic ecosystems and wildlife. PET in landfills does not decompose easily and occupies space long-term. Effective waste management practices, including robust recycling infrastructure, product take-back programs, and incentives for proper disposal, are critical to minimizing these negative environmental consequences. Without proper disposal, the widespread use of PET packaging can contribute significantly to plastic pollution on both local and global scales.

Potential for Reuse

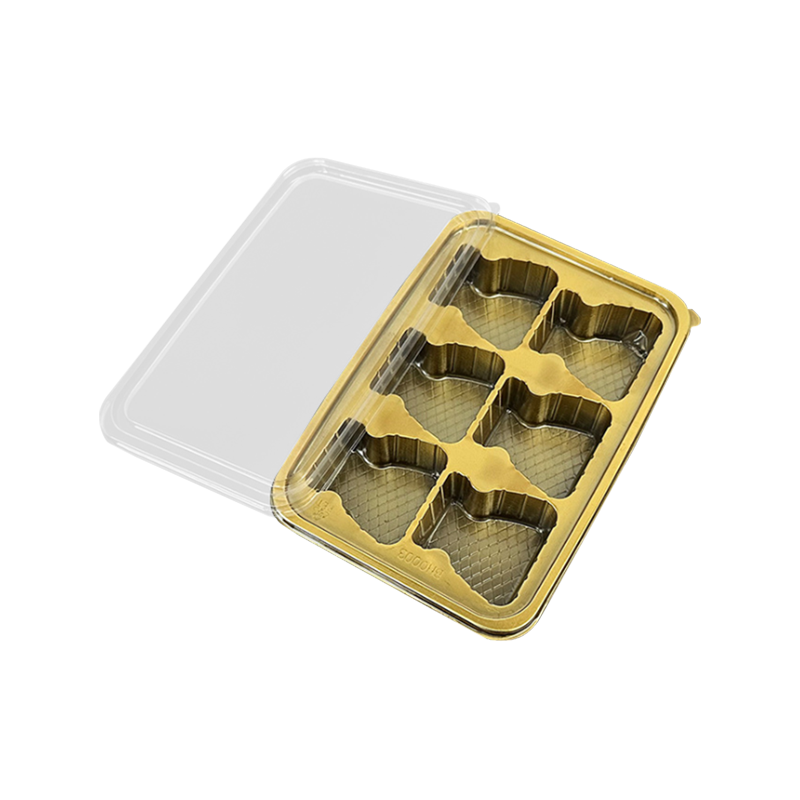

The design of a transparent dome PET packaging box allows for repeated reuse, which can help reduce environmental impacts associated with single-use plastics. Consumers can repurpose these boxes for storage, organizing small items, or displaying products, extending their functional lifespan and reducing the need for additional packaging. Reuse not only reduces material consumption but also mitigates the overall environmental footprint by lowering the volume of packaging entering the waste stream. Encouraging a circular approach, where packaging is designed for multiple uses before recycling, can significantly improve the sustainability profile of PET boxes.

Alternatives and Sustainability Considerations

Although PET offers advantages in durability, transparency, and recyclability, it is still a non-renewable plastic. Alternative packaging materials, such as biodegradable plastics, compostable polymers, or renewable-resource-based materials (e.g., molded pulp or cellulose-based domes), may provide a lower environmental impact in certain applications. Sustainable design strategies for PET packaging—such as reducing material thickness, minimizing over-packaging, or incorporating higher percentages of recycled PET—can improve environmental performance. Companies should also consider the end-of-life pathway for the packaging, including ease of recycling or composting, when selecting materials. These measures align with global trends toward sustainable packaging and circular economy principles.

- The company requires rigorous, using a high starting point, trustworthy, quality, and actively develop and innovate, the pursuit of excellence route!

CONTACT US

- Tel: +86-18867945666

- E-mail: [email protected]

- Add: No.11 Huafeng Road, Anhua Community, Anhua Town, Zhuji City, Shaoxing, Zhejiang, China

GET A QUOTE

Copyright @ Donghang Polymer Material Technology Co., Ltd. All Rights Reserved.

English

English عربى

عربى Español

Español