Web Menu

Product Search

Exit Menu

How does the Plastic Fruit Sushi Box reshape the ready-to-eat food market?

What is Plastic Fruit Sushi Box?

Basic definition:

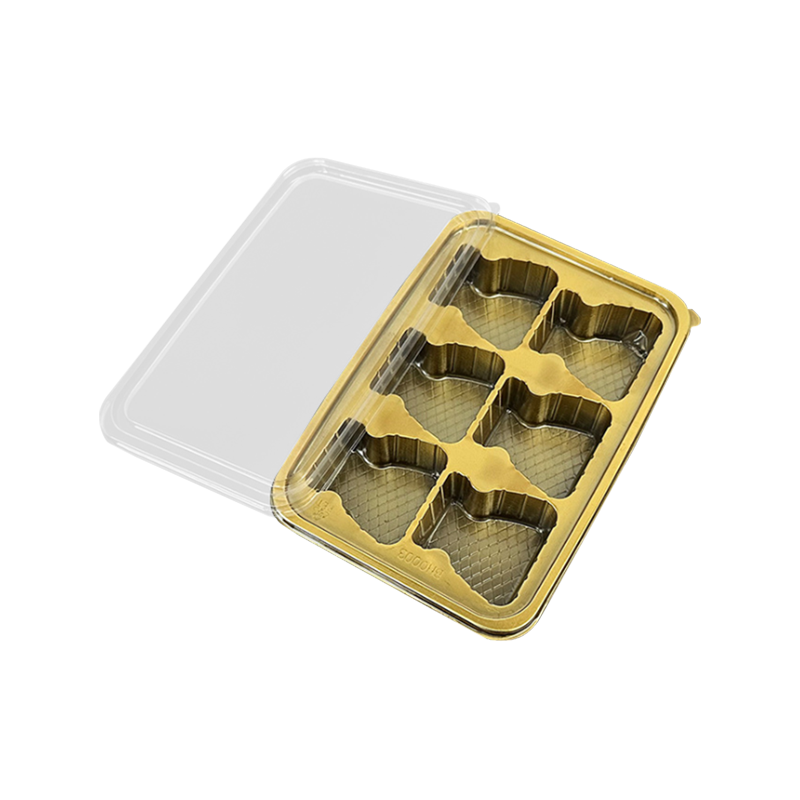

Plastic Fruit Sushi Box is a transparent plastic box specially used for packaging, displaying and storing fruit sushi. Its shape is usually rectangular or with a lid and compartment design to adapt to the shape and size of fruit sushi. This product is not only easy to transport and sell, but also meets the current high standards of consumers for "food visualization" and "instant convenience".

Material characteristics:

Fruit sushi boxes are mostly made of food-grade PP (polypropylene) or PS (polystyrene). These materials have the following advantages:

Safe and non-toxic: Meet food contact level requirements to ensure food safety

The PP (polypropylene) or PS (polystyrene) materials commonly used in fruit sushi boxes are all food-grade certified to ensure that no harmful substances are released when in contact with food. Compared with ordinary industrial plastics, food-grade plastics have strict restrictions on heavy metal content, plasticizers, etc., and do not contain ingredients that are harmful to health such as bisphenol A. This provides basic health protection for packaging fresh fruits and perishable foods such as sushi, and consumers can use it with peace of mind without worrying about food contamination.

High transparency: The box is crystal clear and shows attractive colors

High transparency is one of the key characteristics of plastic fruit sushi boxes. PS and some PP materials can achieve glass-like clarity, making the rich colors and textures of the fruit sushi in the box clear at a glance, greatly improving the display effect. This "visible freshness" not only increases consumers' desire to buy, but also helps merchants achieve better brand display effects. It is especially suitable for retail scenarios such as supermarket refrigerators, convenience store shelves, and takeaway platforms.

Strong low-temperature resistance: worry-free refrigeration, keep the taste fresh

Fruit sushi usually needs to be refrigerated to maintain its taste and texture. Therefore, the plastic materials used must have good low-temperature resistance. PP and PS materials can still maintain a stable structure below 0°C and will not become brittle or cracked due to freezing. The packaging box can also remain intact during cold chain transportation, avoiding problems such as water seepage and deformation, extending the shelf life of food, and providing merchants and consumers with a more secure storage experience.

Lightweight and pressure-resistant: Prevents extrusion damage without increasing the burden of transportation

Another major advantage of plastic fruit sushi boxes is light weight and high strength. Compared with traditional glass or thick paper packaging, PP/PS materials are lighter, have lower transportation costs, and are convenient for large-scale stacking and distribution. At the same time, the material itself has a certain elasticity and compressive strength. Even if it encounters extrusion and collision during the logistics process, it can effectively protect the internal food from being flattened or deformed, ensuring the integrity of the appearance and the value of the product.

High-end material selection: anti-fog treatment and PET material improve freshness and visual experience

In order to meet the needs of the higher-end consumer market, some fruit sushi boxes use anti-fog treatment or switch to PET (polyethylene terephthalate) material. The anti-fog coating can prevent water vapor from condensing on the inner wall due to temperature difference, thereby maintaining visual clarity; PET has both excellent transparency and toughness, and is more environmentally friendly and has high recycling value. These material upgrades not only improve the texture of the product, but also conform to the general trend of green environmental protection and consumption upgrading.

Some high-end products also add anti-fog treatment or use PET material to further enhance the visual effect and preservation ability.

Design intention:

Traditional general-purpose food containers have gradually exposed many deficiencies in use, which seriously restricts key links such as product display beauty, transportation safety and taste retention. The birth of plastic fruit sushi boxes is designed and optimized to solve these pain points, which are specifically reflected in the following aspects:

Easy to crush: soft packaging or thin boxes are easy to collapse during transportation, affecting the appearance

Traditional plastic bags or thin-walled lunch boxes are not supportive enough and are easily deformed or even collapsed due to external forces during transportation, directly destroying the neat placement and exquisite appearance of fruit sushi. Fruit sushi is extremely sensitive to appearance. Once deformed, it will affect consumers' appetite and even cause complaints. The special fruit sushi box adopts reinforced structure design and pressure-resistant materials to significantly improve the pressure resistance and ensure stable shape and intact appearance during transportation.

Poor display effect: Some opaque or matte packaging cannot reflect the color beauty of the product

One of the main selling points of fruit sushi is its fresh and bright appearance. However, if matte, dyed or opaque containers are used for packaging, the internal contents will be seriously obscured, so that consumers cannot directly see the freshness and color level of sushi, reducing their willingness to buy. In contrast, transparent plastic boxes designed for display have a high-gloss and translucent appearance, which not only fully shows the layered beauty of fruit and rice, but also enhances the overall brand image.

Weak sealing performance: leading to dehydration, odor, air drying and other problems

Fruit sushi is extremely sensitive to moisture, odor, and temperature changes. Traditional packaging has poor sealing, which can easily cause internal moisture to evaporate, causing rice to become hard, fruit to shrivel, and the taste to deteriorate; it may also absorb odors or odor with other foods, seriously affecting the quality. New fruit sushi boxes are usually equipped with a precise buckle design between the lid and the box body to enhance air tightness. Some products can also be sealed with food-grade membranes to further prevent odor leakage or contamination.

Inconvenient stacking and storage and transportation: irregular packaging shapes affect transportation efficiency

Traditional packaging often has different shapes and lacks modular design, which is not conducive to stacking, stacking and packing, resulting in large space waste and high costs in the logistics and transportation process. At the same time, it is also easy to tilt and collide due to unstable center of gravity. Special fruit sushi boxes are mostly designed with uniform specifications, flat bottom and nestable design, which not only improves storage and transportation efficiency, but also facilitates refrigeration, sales and replenishment of merchants, and makes overall circulation more efficient.

PLASTIC FRUIT SUSHI BOX solves the above problems. It systematically optimizes the appearance structure, sealing performance, compressive strength and other aspects, making fruit sushi more convenient, efficient and beautiful in production, display, transportation and consumption. The lid and box body are mostly designed with snap or nesting methods to ensure a secure closure and easy to open quickly.

Why do merchants choose plastic fruit sushi box?

In scenarios such as fruit sushi retail, takeaway and supermarket display, packaging is not only a tool for loading products, but also an important means of brand communication and sales conversion. The reason why Plastic Fruit Sushi Box has become the first choice of many merchants is that it has shown significant advantages in visual presentation, freshness preservation performance and operational efficiency.

Visual marketing tool: transparent design stimulates purchasing desire and enhances shelf appeal

In the modern retail environment, "visible deliciousness" is one of the key factors affecting consumer decision-making. Plastic Fruit Sushi Box uses high-transparency materials to make the color level and freshness of the product clear at a glance, especially for products with strong visual impact such as fruit sushi.

Shelf display is more eye-catching

In supermarkets or refrigerators, the transparent box can clearly show the color and level of fruit sushi, and with the lighting, it is more bright and attractive, attracting customers to stop and browse. Neat and uniform packaging also enhances the overall shelf beauty, creates a high-end and hygienic product impression, and helps to create a highly recognizable product display system.

Improve impulse buying rate

Consumers can quickly judge the freshness and quality of products through vision, reducing purchase concerns. Transparent packaging truly presents the contents and enhances purchasing confidence, especially for instant food consumption scenarios with short decision-making cycles and emphasis on appearance. Colorful products with packaging display can further stimulate the desire to buy and immediate consumption behavior.

Enhance brand impression

Uniform high-quality packaging helps to establish a professional and reliable brand image, which is suitable for a variety of business scenarios such as chain stores, takeaway delivery, and self-service refrigerators, and strengthens the brand's awareness of hygiene, health, and fashion. Highly transparent materials combined with personalized labeling or printing can also enhance brand recognition and user memory points.

Scientific grid design: anti-smell and anti-squeezing, extending the shelf life of fruit sushi

In the packaging of fragile foods such as fruit sushi, the scientific nature of the structural design is directly related to product quality and user experience. Plastic Fruit Sushi Box comprehensively improves the practicality and professionalism of packaging through anti-mixing design, pressure-resistant structure, and preservation optimization. Its reasonable division effectively isolates ingredients and avoids the mixing of flavors and colors; the shock-absorbing design ensures stability and integrity of appearance during transportation; and good sealing and airflow control extend the freshness of the product. These functions not only improve consumer satisfaction, but also provide stronger protection for merchants in the distribution, display and sales links.

Preventing ingredients from mixing

The box is often equipped with independent divisions or anti-slip grooves, which can effectively prevent fruit juice from flowing into the rice or other food areas, and maintain the original taste of each part. At the same time, it prevents different ingredients from being stained with color or damaged in taste after contact, and improves the overall eating experience and visual neatness.

In addition, the division can also keep the product layout beautiful during transportation, which is conducive to the visual satisfaction of consumers after opening the box, and enhances the feeling of "beauty in time".

Shock absorption and anti-extrusion

Some box types are equipped with bottom support convex points or three-dimensional structures, which can effectively disperse pressure during transportation, buffer collisions and vibrations, prevent sushi from being flattened or shifted during delivery, and maintain the integrity of the appearance. This is particularly critical for improving the quality of takeout and reducing the complaint rate.

At the same time, the stiffer box wall material can also enhance the stacking stability, which is suitable for high-frequency circulation scenarios, such as chain store distribution, e-commerce cold chain transportation and other complex environments.

Longer preservation time

The reasonable internal structure reduces the flow of air in the box, which helps to maintain a low temperature state. Combined with the sealing design, it can effectively slow down the evaporation of water on the surface of the fruit, delay the oxidation rate, maintain the taste and freshness of sushi, and is more suitable for refrigerated storage and delayed sales.

Some box types also support heat-sealed film or use with moisture-absorbing pads to further optimize the microenvironment, extend the preservation time, and meet the merchants' needs for long-term display and distribution.

Cost and efficiency: Lightweight materials reduce logistics costs, and stacking design saves storage space

In the modern food retail and distribution system, packaging not only undertakes the functions of protection and display, but also directly affects operational efficiency and cost control. With its lightweight material, excellent stacking and efficient packaging adaptability, Plastic Fruit Sushi Box has become an ideal choice for merchants to optimize the supply chain. Whether it is from the perspective of saving transportation costs, efficient use of storage space, or rapid advancement of the packaging process, this packaging solution reflects a high degree of practicality and economic value, helping enterprises to improve operational efficiency and service quality in the fierce market competition.

Lightweight materials reduce transportation costs

PP and PS materials are extremely light in weight and are suitable for high-turnover scenarios such as large-scale distribution and express delivery. Compared with traditional packaging materials such as glass and cardboard, it not only greatly reduces the weight burden during transportation, but also reduces fuel consumption and delivery costs. For chain stores, e-commerce platforms and third-party distributors, it can effectively reduce logistics expenses and improve unit cost control. In addition, the lightweight structure is also conducive to manual handling, reducing operational difficulty and personnel fatigue.

Strong stacking

The box body and lid can be nested and stacked, which is not easy to tip over during transportation, and the storage occupies a smaller area, greatly improving warehouse utilization. This design, which is highly compatible with industrial logistics, enables high-density stacking in a limited space to avoid packaging damage or food contamination caused by messy placement. Whether it is a cold storage, a normal temperature storage or a delivery vehicle, it can be flexibly configured to improve inventory turnover and ensure the quality and efficiency of food from production to sales.

High packaging efficiency

Standardized size with automatic film sealing machine or manual rapid packaging, suitable for a variety of business models (central kitchen, e-commerce takeaway, supermarket pre-packaging, etc.). Factories or processing centers can quickly complete batch production and packaging through unified operation templates, reduce manual dependence, and increase delivery speed. For supermarkets, pre-sealed products can be directly put on the shelves for sale, saving on-site operation time; for takeaway platforms, efficient packaging also helps shorten the order cycle and enhance the overall operational smoothness.

Why do consumers choose it?

"What you see is what you get" sense of security

Transparent plastic packaging allows consumers to directly see the true state of fruit sushi, including the freshness of color, neatness of arrangement and freshness of ingredients. This visual transparency greatly reduces consumers' concerns about food quality, especially at a time when food safety is increasingly concerned, transparent packaging has become an important factor in enhancing trust. In addition, clear display also makes it easier for consumers to make purchasing decisions, improving shopping experience and satisfaction.

Portability upgrade

Plastic Fruit Sushi Box adopts a leak-proof buckle design to effectively prevent liquid leakage and accidental opening of the box lid during transportation, ensuring food integrity and hygienic safety. The one-handed opening and closing design allows consumers to easily open the package even when they are busy or on the move, greatly improving convenience. This design is not only suitable for takeaway delivery, but also meets the needs of modern consumers' fast-paced life, allowing fruit sushi to be easily taken away and enjoyed at any time.

Advantages of the leak-proof buckle design of Plastic Fruit Sushi Box:

Sealing guarantee to prevent liquid leakage

The leak-proof buckle design ensures that the box lid and the box body are tightly locked to form a stable seal. In this way, even if the package is shaken, tilted or compressed, it can effectively prevent the leakage of fruit juice or sauce, avoid the contamination of the outer packaging and transportation environment, and keep it clean and hygienic.

Food safety and hygiene protection

The sealed buckle not only prevents the juice from flowing out, but also blocks the entry of external air, dust and microorganisms, reducing the risk of food contamination. Especially in cold chain transportation and multiple handling processes, it is crucial to keep the food fresh and hygienic.

Reduce returns and complaints, and enhance brand image

Customer dissatisfaction caused by damaged and leaked packaging is common in the food delivery industry. The stable sealing performance of the leak-proof buckle greatly reduces such risks, reduces after-sales disputes, enhances consumers' trust in brand products, and helps to establish a good reputation.

Portable and easy to use, improve user experience

The leak-proof buckle is usually designed to be operated with one hand, which is convenient for consumers to open and close the package at any time, especially suitable for take-out, outdoor picnics, commuting and other scenarios. The convenience of use enhances the practical value and market competitiveness of the product.

Adapt to various transportation methods

Whether it is express delivery, delivery staff delivering meals, or users carrying them by themselves, the packaging box will experience various bumps and squeezes. The strong lock of the leakproof buckle ensures that the product remains intact in a complex logistics environment, adapting to modern efficient and diversified distribution needs.

Environmental protection and sustainable considerations

The high-quality leakproof buckle design increases the reuse rate of packaging, and users do not need to frequently change packaging, reducing the waste of disposable plastics, which is in line with the current environmental protection trend and also adds points to the brand's green image.

Advantages compared with traditional packaging

Compared with traditional soft packaging or simple plastic boxes that are easily damaged and poorly sealed, the Plastic Fruit Sushi Box with a leakproof buckle significantly improves the overall packaging quality, which can not only protect the product, but also be convenient to carry, becoming a new favorite of modern food packaging.

Environmental controversy and response

With the increase of environmental awareness, the environmental impact of disposable plastic packaging has become the focus of consumer and social attention. In response to this challenge, many brands have begun to use recyclable or environmentally friendly materials to manufacture fruit sushi packaging boxes to promote recycling and green production. By educating consumers to recycle and reuse correctly, the brand not only reduces the burden of plastic waste on the environment, but also establishes a responsible corporate image in the market, achieving a win-win situation between environmental protection and market demand.

A comprehensive comparison between Plastic Fruit Sushi Box and traditional packaging

In the field of food packaging, PLASTIC FRUIT SUSHI BOX (transparent plastic fruit sushi box) and traditional packaging (paper box, foam box, etc.) each have their own applicable scenarios. This article will conduct a comparative analysis from multiple dimensions such as material safety, functionality, cost, and environmental protection to help merchants and consumers make more informed choices.

Comparison of materials and safety

Traditional packaging such as paper boxes and foam boxes are usually made of ordinary cardboard or expanded polystyrene (EPS). Although paper boxes are environmentally friendly, they are easily deformed by moisture, and some products may contain fluorescent brighteners, which poses certain safety hazards; although foam boxes have certain shockproof properties, they may release harmful substances in high temperature environments and have insufficient waterproof performance. In addition, this type of packaging is usually opaque, and consumers cannot directly see the food inside, affecting the purchasing experience.

In contrast, Plastic Fruit Sushi Box uses food-grade PP (polypropylene) or PS (polystyrene) materials that meet FDA and EU standards. It is safe, non-toxic, and resistant to low temperatures, making it particularly suitable for refrigerated storage. It has excellent waterproof and oil-proof properties, better sealing effect, and effectively ensures the freshness of food. The highly transparent design allows the color and texture of the product to be clearly seen, greatly enhancing the visual appeal and consumer trust. Overall, plastic fruit sushi boxes are significantly superior to traditional packaging in terms of food safety, durability and display effect, and are an ideal choice for modern fruit sushi packaging.

|

Comparison Aspect |

Traditional Packaging (Paper Box/Foam Box) |

Plastic Fruit Sushi Box |

|

Material |

Ordinary cardboard, expanded polystyrene (EPS) |

Food-grade PP (Polypropylene), PS (Polystyrene), compliant with FDA/EU standards |

|

Safety |

May contain fluorescent whitening agents; foam boxes may release harmful substances at high temperatures |

Non-toxic and odorless, resistant to low temperatures, suitable for refrigerated foods |

|

Water Resistance |

Cardboard easily deforms when wet; foam boxes offer shock resistance but are not waterproof |

Completely waterproof and oil-proof, with superior sealing performance |

|

Transparency |

Opaque, cannot directly see contents |

High transparency design, showcases food color and texture clearly |

|

Durability |

Easily affected by moisture, prone to damage |

Strong and durable, resistant to pressure and impact |

|

Visual Appeal |

Poor display effect, less attractive to consumers |

Vibrant colors, enhances purchase desire |

Functional comparison

Traditional packaging such as paper boxes and foam boxes have certain functional limitations. Paper boxes usually do not have a compartment design, which makes it easy for food to mix together, affecting the taste and appearance; at the same time, paper boxes are susceptible to moisture and have poor preservation effects. Although foam boxes have certain thermal insulation properties, they are not breathable enough, which affects food quality. In addition, paper boxes are soft and collapsed, and foam boxes are large in size, which is not convenient to carry. They are suitable for short-distance delivery or scenarios with low cost requirements.

In contrast, Plastic Fruit Sushi Box adopts a multi-compartment layered design to effectively prevent food from being squeezed and odor-smeared, and maintain the independent flavor of each ingredient. It has good sealing performance and significantly extends the shelf life of food. The light and stackable characteristics make it very suitable for takeaway delivery and retail display, especially for diversified use scenarios such as high-end catering, convenience stores and takeaway. Overall, plastic fruit sushi boxes perform better in terms of freshness preservation, anti-odor and portability, meeting the multiple needs of modern food packaging.

|

Comparison Aspect |

Traditional Packaging (Paper Box/Foam Box) |

Plastic Fruit Sushi Box |

|

Compartment Design |

Usually no compartments, food tends to mix |

Multi-compartment design effectively prevents crushing and flavor mixing |

|

Preservation Effect |

Paper boxes absorb moisture easily; foam boxes have poor breathability, limited preservation |

Excellent sealing performance, extends food freshness |

|

Portability |

Paper boxes collapse easily; foam boxes are bulky and inconvenient to carry |

Lightweight and stackable, suitable for takeout and retail |

|

Application Scenarios |

Suitable for short-distance delivery or low-cost packaging needs |

Ideal for high-end dining, takeout, and diverse convenience store uses |

Comparison of cost and environmental protection

In terms of cost, paper boxes are relatively cheap but easy to damage in traditional packaging, while foam boxes are relatively expensive, but have a certain cushioning and shockproof effect, which is suitable for short-term use needs. In terms of environmental protection, although paper boxes are degradable, it is more difficult to recycle if the surface is coated; foam boxes are difficult to degrade and cause greater pollution to the environment. In contrast, although the unit price of Plastic Fruit Sushi Box is higher, it has stronger durability and can be reused or recycled and cleaned, which improves the cost-effectiveness of long-term use. In terms of environmental protection, the PP and PS plastics used have the potential for recycling. Although they may still have an impact on the environment if not handled properly, some brands have begun to launch degradable versions to promote the sustainable development of packaging. Overall, traditional packaging is suitable for short-term cost control, while plastic fruit sushi boxes have more advantages in durability and environmental sustainability.

Plastic Fruit Sushi Box has comprehensive application scenarios from catering to retail

Due to its excellent design and functionality, Plastic Fruit Sushi Box is widely used in catering, takeaway delivery, retail convenience stores and special events. Whether it is to enhance the brand image and customer experience of sushi restaurants and light food brands, ensure the integrity of food during takeaway delivery, enhance the shelf appeal of supermarkets and convenience stores, or meet the diverse needs of wedding banquets, e-commerce direct mail, etc., this plastic sushi box can provide an efficient solution. Its transparent, highly sealed, shockproof and customizable characteristics make the product have obvious advantages in visual presentation, freshness preservation performance and logistics efficiency, helping brands improve market competitiveness and user satisfaction.

Plastic Fruit Sushi Box is widely used in catering, takeaway delivery, retail convenience stores and special events with its excellent design and functions. Whether it is to enhance the brand image and customer experience of sushi restaurants and light food brands, ensure the integrity of food during takeaway delivery, enhance the shelf appeal of supermarkets and convenience stores, or meet the diverse needs of wedding banquets, e-commerce direct mail, etc., this plastic sushi box can provide efficient solutions. Its transparent, highly sealed, shockproof and customizable characteristics make the product have obvious advantages in visual presentation, freshness preservation and logistics efficiency, helping brands improve market competitiveness and user satisfaction.

Catering industry: enhance brand image and customer experience

Sushi restaurants & Japanese restaurants

In sushi restaurants and Japanese restaurants, Plastic Fruit Sushi Box, with its transparent design, allows customers to intuitively see fresh ingredients, greatly enhancing their desire to buy. Its compartment design effectively prevents sushi from deforming during transportation and display, maintaining the beauty and integrity of the product. At the same time, the packaging supports customized LOGO and brand colors to help merchants strengthen visual recognition and enhance brand image. This packaging is widely used in a variety of products such as fruit sushi, sashimi platters and sushi combination sets to meet diverse catering needs.

Light salad shops & healthy meal brands

In light salad shops and healthy meal brands, the Plastic Fruit Sushi Box is particularly suitable for salads with sauces due to its leak-proof sealing design to prevent liquid leakage. The multi-compartment layered design can separate ingredients such as fruits, nuts, and proteins to keep the ingredients fresh and taste independent. This packaging is widely used in healthy foods such as fruit yogurt cups, quinoa salads and low-calorie bento boxes, meeting consumers' dual needs for convenience and quality.

Takeaway and delivery: ensuring food is delivered intact

Takeaway platform

Plastic Fruit Sushi Box has shock and pressure resistance functions, which effectively reduces the risk of food damage during transportation. Its transparent cover and buckle design ensure that the packaging is not easily opened or spilled during transportation, ensuring the integrity and hygiene of the food. This packaging is widely used in sushi takeaway, fruit cutting boxes and various dessert cups, improving the safety and user experience of takeaway delivery.

Fresh instant delivery

In fresh instant delivery, Plastic Fruit Sushi Box is particularly suitable for ready-to-eat foods that need to be refrigerated due to its excellent fresh-keeping performance. The packaging can be used in conjunction with ice packs or insulation layers to further extend the shelf life of the product and ensure that the ingredients are fresh and delicious. The packaging is widely used in a variety of products such as pre-made fruit sushi, cold sashimi and ready-to-eat seafood platters to meet high-quality delivery needs.

Retail and convenience stores: attracting impulse purchases

Boutique supermarkets

In high-end retail environments such as boutique supermarkets such as Ole' and City'Super, the Plastic Fruit Sushi Box greatly enhances the visual appeal of the shelf with its high transparency design and exquisite plating effect. This packaging not only perfectly displays the fresh color and rich layers of the product, but also attracts more customers to stop and buy, enhancing their desire to buy. This packaging is very suitable for products positioned in the high-end market, giving the product higher added value and pricing space. It is widely used in a variety of products such as ready-to-eat fruit sushi and cold party platters, meeting consumers' dual needs for quality and beauty and improving overall sales performance.

Convenience stores

In convenience stores such as 7-11 and FamilyMart, the Plastic Fruit Sushi Box greatly facilitates the neat display and management of the shelf with its standardized size design. At the same time, its lightweight material effectively reduces logistics and transportation costs and improves delivery efficiency. This packaging is particularly suitable for portable fruit sushi and small-portion desserts, meeting consumers' needs for convenience and deliciousness in a fast-paced life, and helping convenience stores increase product sales and customer satisfaction.

Special scenarios: from event catering to e-commerce direct mail

Event catering

In event catering scenarios such as wedding banquets and business meetings, Plastic Fruit Sushi Box provides customizable special-shaped packaging, such as round and heart shapes, which perfectly meet the needs of different themes and enhance the overall atmosphere of the event. Its stacking design is not only convenient for transportation, but also saves banquet table space, making the table neat and beautiful. This packaging is widely used in buffet sushi towers and fruit dessert tables, helping events present a high-end and professional catering experience.

E-commerce direct mail & gift market

In the e-commerce direct mail and gift market, Plastic Fruit Sushi Box has a shockproof design and cold chain transportation compatibility to ensure that the product remains intact and fresh during long-distance transportation. The packaging can also be paired with ribbons or customized greeting cards to enhance the exquisiteness and added value of the gift. This packaging is widely used in holiday-limited sushi gift boxes and healthy light meal subscription packages, meeting consumers' dual needs for high-quality gifts and convenient delivery.

How to customize Plastic Fruit Sushi Box?

Size Selection Guide

Plastic Fruit Sushi Box offers a variety of size options to meet the needs of different consumption scenarios. Single-serving packaging is suitable for fast-paced takeout and portable ready-to-eat, making it convenient for consumers to enjoy at any time. Party packs or family packs have larger capacity and are suitable for multiple people to share or use at parties. While improving user experience, they also meet the diverse needs of different sales channels. Flexible size design helps brands better enter the market and cover more customer groups.

Small size:

The small-size packaging capacity provided by Plastic Fruit Sushi Box is usually between 100ml and 300ml, and is designed for single-person portable scenarios. It is commonly found in office fast food, convenience store refrigerated areas, and campus ready-to-eat markets. It is suitable for single-serving fruit sushi, fruit yogurt cups, desserts and other products. Its small and lightweight features allow consumers to carry it easily and enjoy it at any time even when commuting or moving. It is an ideal choice to meet the fast-paced lifestyle.

Medium size:

The capacity of the medium-sized Plastic Fruit Sushi Box is about 400ml to 700ml, which is suitable for standard takeaway packages or retail packaging. It is very suitable for holding combination sushi, fruit platters, healthy light salads, etc., and can take into account portability and rich content. This size is widely used in takeaway platforms, fresh food delivery and healthy catering brands, and is the main packaging chosen by most consumers on a daily basis.

Large size:

The capacity of large-size packaging is usually above 800ml to 1500ml, suitable for family sharing, multi-person dinners or holiday gatherings. It can accommodate more ingredients and support complex and diverse plating methods, such as fruit sushi platters, cold meal combinations, customized gift boxes, etc., especially suitable for high-end supermarkets, party scenes and e-commerce gift sales. Large capacity not only improves the product display effect, but also enhances the brand's high-end sense and added value.

Customized size and special-shaped boxes:

In order to meet the personalized needs of specific markets and brands, Plastic Fruit Sushi Box also supports customized size and special-shaped structure design. Brands can choose unique shapes such as round, heart-shaped, and tower-shaped according to product types, combined with functional components such as exclusive partition trays, sauce boxes, and ice packs to achieve differentiated display and enhance user experience. This flexible customization capability is particularly suitable for wedding banquet customization, e-commerce gift boxes, high-end gift markets, etc., further expanding the boundaries of product application.

Brand exposure opportunities

Customization is an important means for brands to create differentiation. Through laser engraving or screen printing technology, the brand LOGO and exclusive patterns can be clearly displayed on plastic boxes to enhance visual recognition. Customizing exclusive colors not only enhances the overall beauty of the packaging, but also strengthens the brand tone and market recognition. High-quality brand presentation helps companies stand out in the fiercely competitive market and enhance consumer loyalty.

Special function extension

In addition to basic packaging, Plastic Fruit Sushi Box also supports a variety of functional customization. The additional sauce box design meets the user's needs for ingredient separation, is easy to carry and avoids odor contamination. In response to environmental protection demands, degradable or bio-based material versions are launched, taking into account sustainable development and product performance. Diversified functional expansion not only enhances product added value, but also complies with modern consumers’ emphasis on health and environmental protection, helping the brand establish a good image.

- The company requires rigorous, using a high starting point, trustworthy, quality, and actively develop and innovate, the pursuit of excellence route!

CONTACT US

- Tel: +86-18867945666

- E-mail: [email protected]

- Add: No.11 Huafeng Road, Anhua Community, Anhua Town, Zhuji City, Shaoxing, Zhejiang, China

GET A QUOTE

Copyright @ Donghang Polymer Material Technology Co., Ltd. All Rights Reserved.

English

English عربى

عربى Español

Español