Web Menu

Product Search

Exit Menu

How well does the lid of the Plastic Fruit Sushi Box maintain an airtight or leak-proof seal for wet or juicy fruit items?

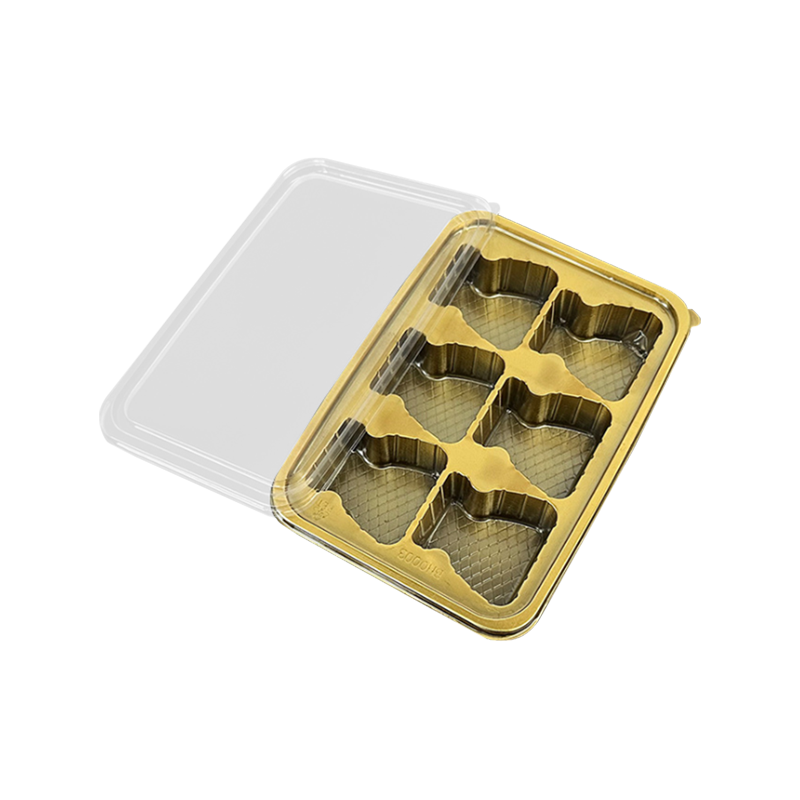

The sealing ability of the Plastic Fruit Sushi Box depends heavily on the engineering precision between the lid and the base structure. A properly aligned lid should match the rim of the base with minimal tolerance deviation to prevent microgaps where liquid or air could enter or escape. Many high-performance models use multi-point snap-lock systems around the perimeter, which apply even pressure and reduce the risk of partial closure. These locking features must be uniform across all sides to ensure balance and avoid warping under stress. If the locking tabs are too short, thin, or inconsistently molded, they may not resist internal pressure generated by juicy fruit content. Furthermore, the locking interface should be designed with anti-slip grip zones, which improve usability and prevent user error during closure, especially in environments such as food prep stations or retail shelves where speed and accuracy are critical.

For superior leak-proof functionality, the Plastic Fruit Sushi Box may be equipped with an embedded gasket—typically made of food-grade silicone or thermoplastic elastomer—along the inside of the lid. This gasket enhances the compression seal between the lid and the rim of the box, forming a more effective barrier against juice or moisture escape. The presence of a gasket is especially relevant when packaging high-moisture foods like citrus segments, watermelon, or soy-sauce-dressed sushi rolls. The design of the gasket must ensure complete circumferential contact without gaps, and the material used must retain its elasticity over time and under refrigeration. Gasket-enhanced lids also offer improved vacuum effect when closed properly, reducing air exchange and prolonging freshness. If the gasket is removable, it should be tightly seated to prevent contamination buildup, and designed to endure repeated washing or sterilization without deformation.

The base and lid of the Plastic Fruit Sushi Box must be made from materials that resist bending, warping, or cracking when exposed to various temperatures, moisture levels, or stacking pressure. Common materials include PET (polyethylene terephthalate), PP (polypropylene), and PS (polystyrene), but the grade and formulation significantly influence sealing behavior. A too-flexible lid may not hold tight against the base when internal pressure from fruit juices accumulates, leading to corner leaks. On the other hand, overly rigid plastics can become brittle under cold conditions, increasing the risk of cracks along the sealing edge. The optimal material strikes a balance between rigidity for structural support and flexibility for sealing performance. The plastic used must have a low coefficient of thermal expansion to prevent micro-separation of the lid and base in temperature-variable environments, such as during refrigerated transportation or transition from cold storage to room display.

Real-world conditions for Plastic Fruit Sushi Boxes often involve movement—whether during consumer handling, retail display, or bulk shipping. Therefore, the lid must stay sealed under moderate jostling, tilting, and impact from stacking. Boxes intended for use with wet contents should include a recessed channel or overflow catch near the sealing edge that traps any moisture attempting to migrate outward, effectively adding a second barrier to leakage. The internal design may also include ribbing or textured base surfaces that elevate the food slightly above pooled juices, minimizing contact and reducing pressure at the seal line. Manufacturers often test such products using simulated transit conditions or by filling them with colored liquids to detect early signs of leakage. The result should be a box that remains dry externally and stable even when turned on its side or lightly squeezed during packing and transport.

In logistics, the Plastic Fruit Sushi Box often interacts with outer packaging elements such as shrink wrap, cartons, display trays, and cold storage bins. These external forces can exert downward or lateral pressure on the lid, and if the box lacks mechanical strength or uniform sealing pressure, the lid may pop open or deform slightly, compromising the leak-resistant function. For this reason, commercial-grade boxes should be designed to endure moderate compression without structural failure. Reinforced edge walls and thicker lid flanges help distribute stress more evenly across the seal line. Some advanced designs feature interlocking ridges on the lid and base to reduce lid separation during vibration or compression. Proper compatibility with automation equipment—like conveyor lines or robotic packing arms—also requires the box to resist torsional stress during handling, without causing lid displacement.

- The company requires rigorous, using a high starting point, trustworthy, quality, and actively develop and innovate, the pursuit of excellence route!

CONTACT US

- Tel: +86-18867945666

- E-mail: [email protected]

- Add: No.11 Huafeng Road, Anhua Community, Anhua Town, Zhuji City, Shaoxing, Zhejiang, China

GET A QUOTE

Copyright @ Donghang Polymer Material Technology Co., Ltd. All Rights Reserved.

English

English عربى

عربى Español

Español