Web Menu

Product Search

Exit Menu

How does the thickness and structure of PET plastic food trays affect their durability and resistance to cracking or deformation under pressure?

1. Barrier Properties to Moisture and Oxygen

PET plastic food trays are designed to provide superior barrier properties against moisture and oxygen, two critical factors that influence the shelf life and quality of food products. PET (Polyethylene Terephthalate) is known for its low permeability to oxygen, which helps in slowing down the oxidation process. Oxidation can cause food to lose flavor, color, and nutritional value, particularly for perishable items like meats, fresh produce, and dairy products. By preventing excessive oxygen exposure, PET plastic trays significantly reduce the rate at which these products spoil, maintaining their taste and texture for longer periods.

Additionally, PET is also highly resistant to moisture, which is beneficial in preventing both the drying out and sogginess of food. When moisture is trapped inside the tray, it can lead to mold growth, bacterial contamination, or degradation of the food's quality. Many PET food trays are designed with tight-fitting lids or vacuum-sealing options that help lock in moisture levels and prevent the food from becoming dry or losing its inherent juiciness. Modified atmosphere packaging (MAP), which often uses PET trays, replaces the oxygen inside the packaging with nitrogen or carbon dioxide, further enhancing the shelf life by reducing oxygen exposure. This combination of moisture retention and oxygen control is particularly valuable for foods that are sensitive to spoilage, such as fresh meats, salads, and baked goods.

2. Temperature Control and Insulation

The design of PET plastic food trays contributes to maintaining the ideal temperature for food storage and transportation. PET is an excellent material for insulation, helping to stabilize the temperature inside the tray. This is particularly important during shipping and storage, where temperature fluctuations can significantly impact the freshness of food. For instance, fresh foods like meats, dairy, or ready-to-eat meals require consistent cold storage to prevent bacterial growth and spoilage. The PET trays, when combined with sealed lids, help to retain the cold temperature longer, preventing rapid thawing or temperature changes that could harm the food.

Moreover, PET trays designed for hot foods often feature improved structural integrity to withstand high temperatures without warping or deforming. Some PET food trays are designed to be heat-resistant, ensuring that hot meals remain at the desired temperature during transportation or in the retail environment. The ability of PET plastic trays to retain and control temperatures helps minimize food waste and ensures that food products arrive at their destination in optimal condition.

3. Structural Integrity and Fit

The structural design of PET plastic food trays is engineered to provide durability and stability, ensuring that food products are protected during handling, transportation, and storage. PET trays are typically molded to fit specific food types precisely, which reduces the risk of crushing, shifting, or contamination. The tight fit of food within the tray also minimizes air pockets, which can contribute to the acceleration of spoilage by promoting uneven temperature distribution or moisture buildup.

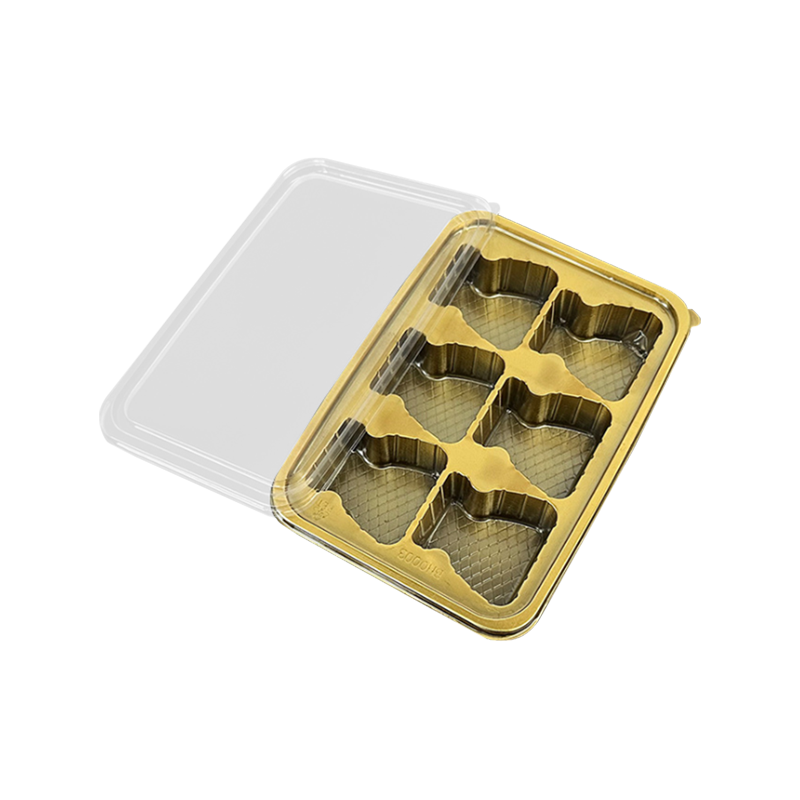

For example, products like fresh fruits, vegetables, and fragile bakery goods benefit from PET food trays that hold them securely without applying excessive pressure. By preventing squashing and bruising, the food maintains its visual appeal and freshness. Similarly, the deep-dish designs of PET trays are well-suited for items like meats and frozen foods, where insulation is essential to maintain optimal conditions. PET trays are also available in compartmentalized designs that help separate different food items, maintaining their integrity and preventing them from mixing or touching one another, further protecting the food’s quality.

4. Anti-fog and Clarity

Condensation and fogging inside food packaging can be a significant issue, particularly for perishable products like fruits, vegetables, or salads. PET plastic food trays are often designed with anti-fog technology that prevents moisture from forming on the interior surface of the tray. This is especially important for maintaining product visibility and appeal. When food is properly packaged in a clear, fog-free container, consumers can easily assess its quality and freshness, leading to better sales outcomes.

For products like fresh-cut vegetables or deli meats, where aesthetics and visual appeal are crucial, anti-fog PET food trays help keep the food looking fresh and vibrant. Without fogging, the food inside the tray remains visible, enhancing its shelf appeal. In addition to improving visual presentation, the absence of moisture on the tray’s surface also prevents excess water from pooling around the food, which could otherwise lead to spoilage or degradation of texture, such as sogginess in leafy greens or rubbery fruit surfaces.

5. Sealing and Lid Integration

One of the key design features that impact the preservation of food in PET plastic food trays is the sealing system used in conjunction with the tray. Sealing not only prevents contamination but also plays a significant role in preserving food by limiting exposure to oxygen, moisture, and external contaminants. Proper seals prevent air from entering the tray, which is crucial in extending the shelf life of products. Sealing mechanisms can range from simple snap-on lids to heat-sealed or vacuum-sealed options, with each offering varying degrees of airtight protection.

For example, vacuum-sealed PET trays create an internal atmosphere with little to no oxygen, effectively slowing down the degradation process of the food and reducing microbial growth. Heat seals, on the other hand, are often used for packaging products that require longer shelf life or to ensure that the tray is tamper-evident. The integration of a well-fitting lid or seal also prevents physical damage to the food by keeping it secure within the tray, reducing the chances of crushing or moisture leakage that could affect quality.

- The company requires rigorous, using a high starting point, trustworthy, quality, and actively develop and innovate, the pursuit of excellence route!

CONTACT US

- Tel: +86-18867945666

- E-mail: [email protected]

- Add: No.11 Huafeng Road, Anhua Community, Anhua Town, Zhuji City, Shaoxing, Zhejiang, China

GET A QUOTE

Copyright @ Donghang Polymer Material Technology Co., Ltd. All Rights Reserved.

English

English عربى

عربى Español

Español