Web Menu

Product Search

Exit Menu

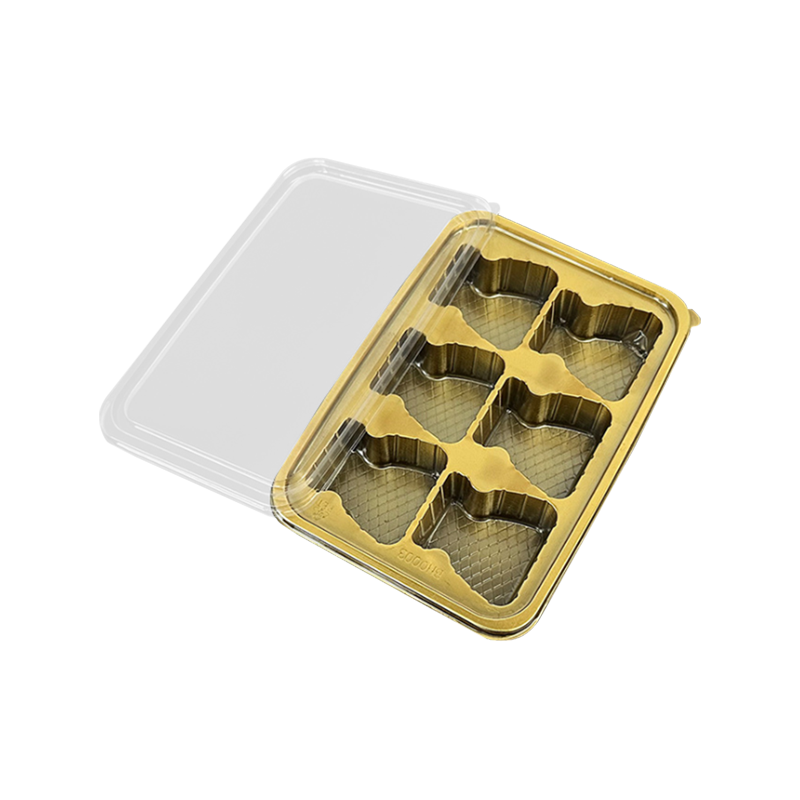

How does the Nine Grid PET Blister Packaging Box prevent product movement within each compartment, especially for delicate items requiring precise positioning?

Precision-Formed Compartment Dimensions for Tight Fit Retention

The Nine Grid PET Blister Packaging Box prevents internal movement primarily through precision thermoforming, which allows manufacturers to create compartments with exceptionally accurate dimensional tolerances. Using high-quality PET sheets combined with controlled heating and vacuum forming technologies, each cavity is molded to match predetermined shapes with deviations often within fractions of a millimeter. These controlled tolerances ensure that the product fits securely inside the compartment, minimizing undesired clearance that could allow lateral or vertical shifting. This level of precision is especially important for delicate items—such as glass components, electronics, or medical accessories—that require consistent and predictable housing geometry to prevent friction damage or micro-abrasion. PET’s excellent formability allows the cavity depth, angles, and radii to be tailored to the unique contours of the product, effectively creating a custom-shaped retention system without needing secondary padding materials. This structural “conforming fit” dramatically enhances stability during transportation, handling, or vertical stacking.

Structural Reinforcement Ridges and Contoured Cavity Walls

The internal design of each compartment incorporates strategically engineered reinforcements such as ribs, chamfers, and curvature zones that serve both mechanical and stabilizing functions. Instead of flat, uniform walls, compartments often feature contoured surfaces designed to cradle the product from multiple angles. These curves and reinforcements not only strengthen the tray’s overall rigidity but also reduce the available free volume where items might shift, bounce, or rotate. By increasing the number of contact points between the packaging and the product, the design distributes forces evenly, reducing stress concentrations that could damage fragile goods. Additionally, reinforced rib structures help maintain wall stiffness even when the packaging is subjected to stacking loads or accidental impacts. The overall effect is a cavity that acts like a supportive frame, holding each item firmly in position and preventing displacement in all directions, even when subjected to mechanical shock or repetitive vibrations.

PET Material Rigidity and Dimensional Stability

Polyethylene Terephthalate (PET), the primary material used in the Nine Grid PET Blister Packaging Box, offers a combination of rigidity and dimensional stability that is particularly advantageous for movement prevention. Because PET has a high modulus of elasticity, it resists deformation even under compressive forces from stacking or external pressure. This ensures that compartment dimensions remain consistent over time, preventing any warping or relaxation that could increase internal clearance. PET’s resistance to temperature fluctuations further protects against expansion or distortion during shipping or warehousing, maintaining the integrity of compartment boundaries. Its inherent structural stiffness acts as a stabilizing force that physically restricts product movement. By holding its form more effectively than softer plastics such as PVC or PP, PET ensures that delicate or high-precision items remain exactly where they were placed throughout the entire distribution chain.

Snap-Lock or Pressure-Fit Lid Retention System

Another significant stabilization mechanism comes from the integration of snap-lock, clamp-fit, or heat-sealed lids that close securely over the compartments. When the lid is applied, it eliminates vertical clearance by applying consistent downward pressure across the entire grid. This pressure ensures that the product cannot rise upward or shift within the cavity during movement. The tight interface between the tray and lid forms a stable containment environment where the product is stabilized from both above and below. This system is especially beneficial for items that must remain perfectly oriented—such as electronic modules, pharmaceutical vials, cosmetic jars, or decorative items. For high-value or extremely delicate products, lidding films or welded seals may be used to create a semi-rigid enclosure that further reduces vibration-induced movement. This dual-surface stabilization method is a key factor in preventing displacement during shipping or high-volume logistics handling.

Anti-Slip Surface Textures and Micro-Grained Finishes

To further enhance immobilization, some Nine Grid PET Blister Packaging Boxes incorporate micro-textured or lightly grained interior surfaces. These textures function by increasing friction between the compartment’s surface and the product, effectively reducing sliding or rotational movement. The textures are subtle enough to maintain full product visibility yet engineered to create surface irregularities that “grip” the product without causing abrasion. This feature is particularly valuable for smooth, polished, or coated items that might otherwise shift easily in a smooth-walled cavity. In applications such as electronics, optical components, or small metal parts, the anti-slip micro-texture helps stabilize items even when packages are tilted, dropped, or subjected to rapid directional changes. By fine-tuning texture depth and patterning, manufacturers can strike a precise balance between aesthetics, frictional control, and material clarity.

- The company requires rigorous, using a high starting point, trustworthy, quality, and actively develop and innovate, the pursuit of excellence route!

CONTACT US

- Tel: +86-18867945666

- E-mail: [email protected]

- Add: No.11 Huafeng Road, Anhua Community, Anhua Town, Zhuji City, Shaoxing, Zhejiang, China

GET A QUOTE

Copyright @ Donghang Polymer Material Technology Co., Ltd. All Rights Reserved.

English

English عربى

عربى Español

Español