Web Menu

Product Search

Exit Menu

How does PET Plastic Food Tray maintain its shape and structural integrity when stacked for storage or shipping?

High-Strength Material Composition and Molecular Structure

PET Plastic Food Trays are manufactured from polyethylene terephthalate (PET), a polymer known for its rigidity, impact resistance, and dimensional stability. The molecular structure of PET allows it to withstand compressive forces without permanent deformation, even under stacked loads. This inherent strength ensures that each tray maintains its flatness and overall geometry, preventing sagging or bowing that could compromise food protection. The semi-crystalline nature of PET contributes to its resistance to creep—a gradual deformation under prolonged stress—so trays retain their shape during extended storage or long-distance shipping. High-quality PET formulations are often enhanced with additives that improve thermal stability and resistance to minor flexing or vibration during transport.

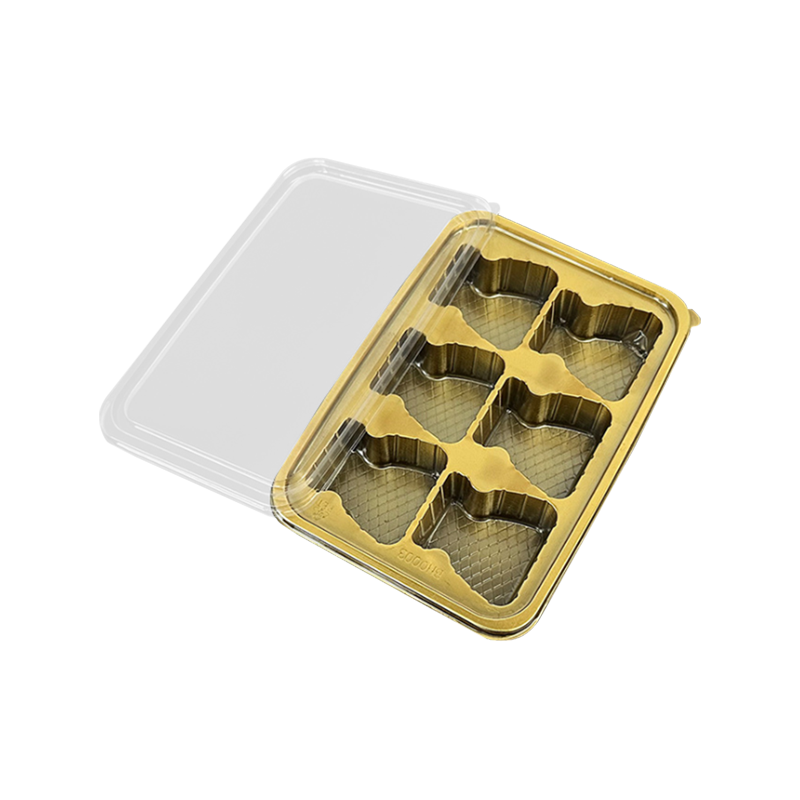

Reinforced Tray Design and Wall Geometry

Structural integrity in stacked PET Plastic Food Trays is achieved not only through material properties but also through intentional design features. Trays often incorporate ribbing, fluted edges, or perimeter ridges that act as load-bearing supports. These geometric reinforcements distribute compressive stress evenly across the tray surface, preventing localized deformation under the weight of multiple stacked trays. Slightly tapered sidewalls also allow trays to nest securely without binding, providing both space efficiency and stability during stacking. Raised bases or reinforced corners further enhance strength, ensuring that trays do not collapse or lose shape when stacked for storage or handling.

Uniform Wall Thickness and Quality Control

Consistency in wall thickness is critical to stacking performance. PET Plastic Food Trays are produced using precision thermoforming or injection molding processes that ensure uniform thickness across the tray. Variations in thickness can create weak points prone to bending or cracking under load. Strict quality control measures, such as dimensional checks and sample load testing, help guarantee that each tray can reliably support the weight of multiple trays stacked above it. Uniform thickness, combined with the tray’s structural design, ensures that even lightweight trays maintain integrity during transport, reducing the risk of deformation that could compromise food protection.

Nestability and Load Distribution

Stackable PET trays are often designed to interlock or nest efficiently without concentrating stress in a single area. Nesting features allow trays to bear compressive loads collectively, with the weight shared across the tray perimeter rather than solely on the central surface. This prevents excessive downward pressure that could cause bending or warping. Nestable designs also minimize tray movement during transport, reducing friction and lateral stress that can lead to scratches, cracks, or buckling. By combining load-sharing geometry with the mechanical properties of PET, the trays maintain their form under real-world storage and shipping conditions.

Thermal and Environmental Stability

PET Plastic Food Trays maintain their stacking integrity across typical storage environments, including refrigerated, ambient, and slightly elevated temperatures. PET has a relatively high glass transition temperature (~70–80°C), which prevents softening under moderate heat exposure, such as in warehouses or transport vehicles. The material also resists moisture absorption, so it does not swell or lose rigidity in humid conditions. This thermal and environmental stability ensures that stacked trays remain flat, aligned, and structurally sound from production to final use, protecting the food contents and maintaining visual appeal.

- The company requires rigorous, using a high starting point, trustworthy, quality, and actively develop and innovate, the pursuit of excellence route!

CONTACT US

- Tel: +86-18867945666

- E-mail: [email protected]

- Add: No.11 Huafeng Road, Anhua Community, Anhua Town, Zhuji City, Shaoxing, Zhejiang, China

GET A QUOTE

Copyright @ Donghang Polymer Material Technology Co., Ltd. All Rights Reserved.

English

English عربى

عربى Español

Español