Web Menu

Product Search

Exit Menu

How does a Plastic Fruit Sushi Box maintain freshness and prevent moisture buildup or condensation when storing temperature-sensitive foods like sliced fruit and sushi?

Material Composition and Food-Safe Barrier Properties

The Plastic Fruit Sushi Box maintains freshness through its use of high-grade polymers such as PET, PP, or PS, which act as stable barrier materials that resist moisture penetration and external contamination. These plastics are selected not only for rigidity and clarity but for their ability to limit gas permeability, reducing oxygen exchange that accelerates oxidation in cut fruit and sushi ingredients. The hydrophobic molecular structure of such plastics prevents surface absorption of liquids, so moisture stays isolated rather than diffusing through the container. This prevents microbial growth and spoiling caused by prolonged humidity exposure. The food-safe resin composition remains non-reactive to acidic fruit juices or sushi vinegar, ensuring flavors remain pure and uncontaminated. By controlling environmental exposure at a molecular and physical level, the container helps maintain both sensory qualities—like taste and texture—and microbiological safety for extended storage durations.

Humidity Control Through Venting or Pressure-Regulating Structural Design

The Plastic Fruit Sushi Box often incorporates engineered vents, micro-valves, or precision tolerances in the lid fitment to regulate internal pressure and humidity. These features allow excess vapor produced by freshly cut fruit, rice, or fish to escape at a controlled rate, preventing condensation droplets from forming on the interior surface. Moisture accumulation inside a sealed container can lead to soggy sushi rice, diluted sauces, and slippery fruit surfaces that degrade user experience. By allowing vapor to vent without compromising containment, the box keeps humidity stable enough to retain fresh textures. Some designs employ a semi-permeable membrane integrated into the lid or tray, enabling gas exchange while blocking liquid transfer. This balances internal climate conditions by preventing excessive moisture buildup, especially when transitioning the product between temperature zones like refrigerator to ambient display, thereby maintaining visual presentation and freshness.

Condensation Prevention Through Anti-Fog Lid Treatments

To enhance product visibility and prevent condensation, many Plastic Fruit Sushi Box models include anti-fog coatings or surface treatments applied to the interior of lids. These coatings modify surface tension so that moisture spreads into a transparent film rather than forming droplets that cloud the surface. Clear visibility is not only a visual merchandising benefit but also reduces internal dehydration by controlling how condensation interacts with the food. The continuous moisture film evaporates and rebalances rather than dripping back onto sushi or fruit, which could alter taste and texture. In refrigerated retail environments, this technology is essential because temperature differential between chilled air and warmer food is one of the primary triggers of fogging. Anti-fog treatment ensures the lid remains optically clear and minimizes water accumulation in localized areas, preserving both hygienic appearance and structural integrity of delicate ingredients.

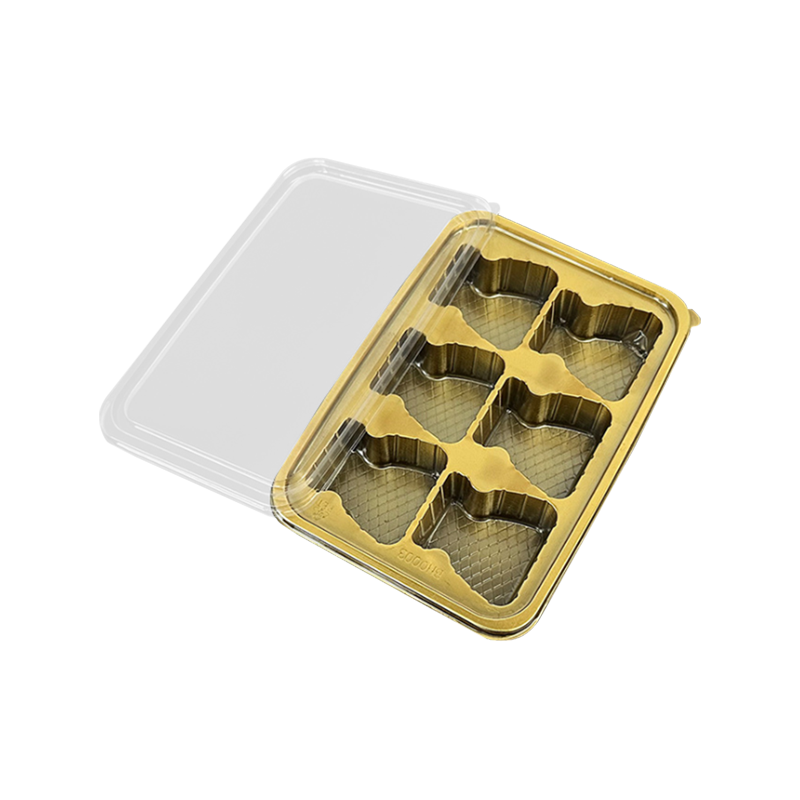

Compartmentalization and Physical Separation of High-Moisture Ingredients

Plastic Fruit Sushi Boxes frequently use segmented layouts, raised platforms, or drip-catch channels to keep moisture-rich ingredients physically separated. Fruits naturally release water and sugars as they sit, while sushi rice absorbs moisture and becomes mushy if directly exposed. By isolating components, the container slows cross-contamination of liquids and maintains intended textural contrast. Dividers or removable trays improve airflow between components, ensuring the entire interior environment has a uniform microclimate rather than forming high-humidity pockets. Some designs even include absorbent pads discreetly placed beneath fruit to capture excess liquid before it can influence the rest of the compartment. This integrated moisture-management architecture is especially valuable for commercial retailers who need to guarantee consistent quality across multiple hours of display or transport, reinforcing freshness from production to consumption.

- The company requires rigorous, using a high starting point, trustworthy, quality, and actively develop and innovate, the pursuit of excellence route!

CONTACT US

- Tel: +86-18867945666

- E-mail: [email protected]

- Add: No.11 Huafeng Road, Anhua Community, Anhua Town, Zhuji City, Shaoxing, Zhejiang, China

GET A QUOTE

Copyright @ Donghang Polymer Material Technology Co., Ltd. All Rights Reserved.

English

English عربى

عربى Español

Español