Product category

Product category

PP Plastic Food Tray Suppliers

-

Environmentally friendly irregular oval gold plastic tray

-

Plastic cake tray with transparent lid

-

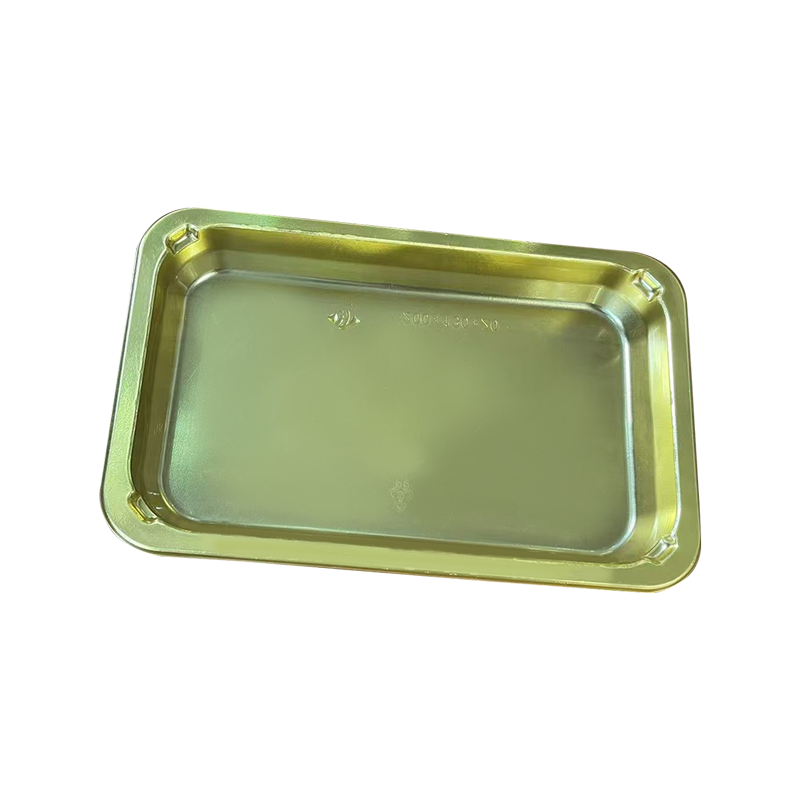

Golden plastic cake tray

-

Disposable frozen food packaging tray

-

Vacuum sealed packaging box for frozen food

-

Disposable PP chocolate tray

-

Disposable PP thickened pastry tray

-

Silver fan-shaped edge circular tray

-

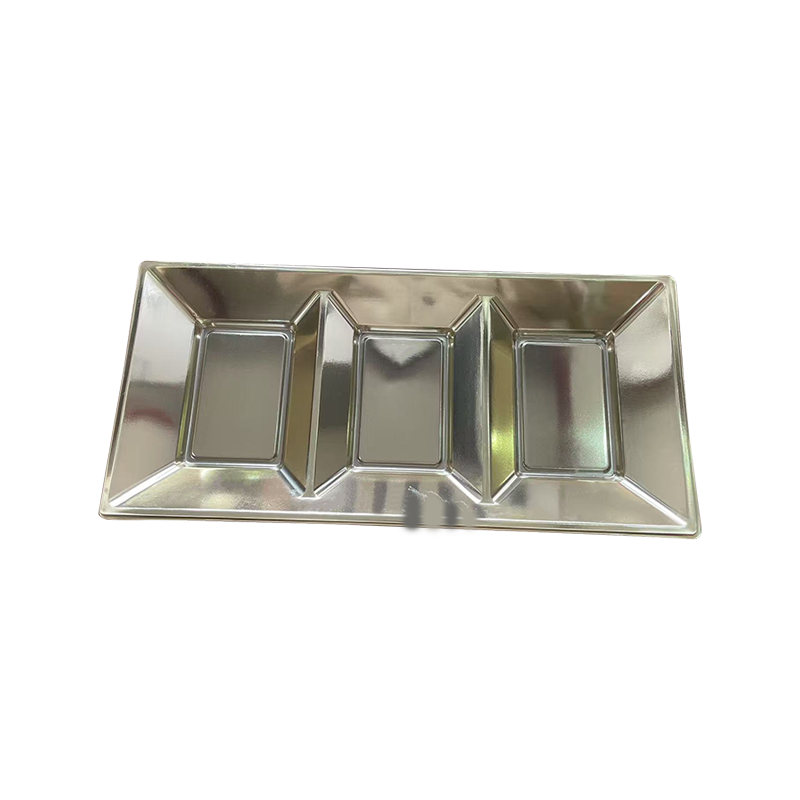

Silver plastic 3-grid snack tray

-

Benefits Of Disposable Tableware

-

Disposable plastic PP material sushi food tray Box

-

Disposable plastic sushi food tray Box

About Us

Donghang Polymer Material Technology Co., Ltd. Was established in February 11, 2015, as a famous China PP Food Boxes Manufacturers and PP Plastic Food Tray Suppliers, the company is a factory in one of the international trade enterprises, specializing in the production of blister trays, blister blisters, plastic packaging trays, packaging trays, pvc & pet folding boxes, hang tags, etc., but also to provide customers with the design of the mold, supporting the undertaking of the processing of a one-stop service, to win the trust of every customer with quality and service!

News

Industry Knowledge Extension

Advantages of PP Plastic Food Trays for Food Safety and Hygiene

PP plastic food trays are recognized for their non-toxic composition, making them a safe and ideal material for direct food contact. Unlike certain types of plastics, such as polycarbonate, which can contain harmful substances like Bisphenol A (BPA), polypropylene is free from these potentially harmful chemicals. This is particularly crucial in food packaging, where the safety of consumers is the top priority. With PP plastic, there is no risk of harmful chemicals leaching into the food, ensuring the food remains uncontaminated and safe to consume. The safety of food packaging materials is governed by strict food safety regulations in many countries, including the U.S. Food and Drug Administration (FDA) and European Union food safety standards. PP plastic food trays are compliant with these regulations, making them an excellent choice for businesses in the food industry. Donghang Polymer Material Technology Co., Ltd. manufactures PP trays with the highest regard for safety and hygiene, ensuring that the trays produced are non-toxic and free from harmful substances. This commitment to quality allows businesses to offer food products that meet safety standards, reassuring consumers that their food is packaged in a safe and secure manner. The absence of BPA and other harmful chemicals not only prevents health risks but also ensures that food retains its natural flavor and quality. Packaging materials that leach chemicals can alter the taste and texture of food, leading to a negative consumer experience. PP plastic's non-toxic properties preserve the authenticity of the food, which is essential for maintaining the product’s original qualities.

The major benefit of PP plastic food trays is their inherent resistance to bacteria and other contaminants. The surface of PP trays is smooth and does not allow bacteria to adhere easily, which minimizes the risk of contamination during storage, transportation, and handling. This is particularly important in food packaging, where contamination can lead to foodborne illnesses and spoilage. PP trays are non-porous and do not absorb moisture, further reducing the potential for microbial growth. Bacteria thrive in environments with moisture and food particles, and contamination can occur quickly in packaging that does not provide an effective barrier. However, PP plastic trays are designed to maintain hygiene by offering an impenetrable surface that resists the growth of harmful bacteria, mold, and fungi. This resistance helps to preserve food quality and ensures that food stays fresh for longer periods. Donghang Polymer Material Technology Co., Ltd. places a strong emphasis on hygiene throughout the manufacturing process. The company follows strict sanitation standards, ensuring that each PP food tray is clean and free from any contaminants. The company’s advanced production techniques, coupled with their commitment to hygiene, allow businesses to provide consumers with food packaging solutions that keep products safe from bacterial contamination, helping to maintain public health standards. The antibacterial properties of PP trays also help in reducing the need for preservatives or artificial chemicals, as food can stay fresh longer in hygienic packaging. This aspect of PP plastic food trays supports the trend toward cleaner, more natural food options, where the packaging plays a vital role in maintaining food safety.

PP plastic food trays are designed to be resistant to various substances that are commonly present in food, such as oils, fats, and food acids. Greasy and oily foods, such as fried snacks, fast food, and deli meats, often require packaging that can withstand contact with these substances without breaking down. PP’s resistance to grease and oil means that it will not degrade or lose its strength when exposed to fatty foods. Similarly, acidic foods like fruits, tomatoes, and sauces that can corrode or weaken certain packaging materials do not affect PP plastic trays. This resistance helps ensure that the food stays properly packaged and free from contamination. Grease and oils can weaken other types of plastic packaging, causing it to lose its structural integrity or develop leaks. However, PP plastic food trays maintain their strength and shape, even when in contact with greasy foods. The surface of PP trays is smooth, preventing oils from seeping through the material, which further ensures that food stays intact during storage and transportation. The food packaging industry places a significant emphasis on maintaining the quality of food products, and PP plastic food trays contribute to this by ensuring that food is packaged securely without the risk of contamination from oils or acids. Donghang Polymer Material Technology Co., Ltd. manufactures PP trays with this essential property in mind, allowing businesses to rely on durable, resistant packaging that can handle a wide variety of food products. The trays help businesses reduce the risk of spoilage or contamination and maintain product quality throughout the supply chain.

PP plastic food trays are capable of withstanding extreme temperature variations, making them suitable for a wide range of food storage and transportation needs. PP is known for its excellent temperature stability, which means that the trays can be used in both freezing and heating environments without compromising their structure or safety. This feature is particularly beneficial in industries where food needs to be stored or transported at varying temperatures, such as frozen meals, chilled products, and ready-to-eat meals that require reheating. For frozen food products, PP trays can withstand freezing temperatures without cracking or becoming brittle. Similarly, when used for hot foods or reheated meals, PP trays maintain their integrity and do not release harmful chemicals when exposed to high heat. This temperature resistance ensures that food stays safe and fresh, no matter the storage or cooking conditions. Donghang Polymer Material Technology Co., Ltd. takes advantage of the excellent temperature stability of PP plastic in their tray production process, ensuring that the trays are suitable for a wide range of food applications. Whether it’s for meals that need to be frozen, kept at refrigerated temperatures, or heated up in the microwave, the company’s PP plastic food trays are designed to perform reliably across various temperature ranges. This contributes to food safety, as it prevents packaging failure and ensures that food stays protected from external elements.

PP plastic food trays are not only easy to clean, but they are also durable enough to be reused multiple times. In industries where hygiene is a top priority, such as in foodservice, catering, and retail, the ability to sanitize packaging materials is critical. PP trays can be easily washed by hand or in industrial dishwashers, and they retain their quality after multiple cleaning cycles. This makes PP trays an excellent choice for businesses looking to minimize waste and reduce packaging costs by using reusable materials. The smooth surface of PP trays makes them resistant to dirt and food particles, ensuring that they are easy to wipe clean without the risk of contamination. Additionally, PP trays do not absorb liquids or odors, which makes them more hygienic than other types of trays that may develop lingering smells or stains after use. This quality allows businesses to provide customers with clean and sanitary food packaging, which is essential for maintaining food safety standards. Donghang Polymer Material Technology Co., Ltd. manufactures PP plastic food trays with this easy-to-clean feature in mind, providing businesses with a cost-effective and sustainable solution for food packaging. By opting for reusable trays, businesses can lower their environmental impact while maintaining high hygiene standards. These trays support the move toward more sustainable and eco-friendly packaging practices, helping companies meet consumer demand for both hygiene and environmental responsibility.

English

English عربى

عربى Español

Español